# Individually Packaged Medical Cotton Swabs: A Revolutionary Choice for Modern Medical Safety

1. [Introduction: Small Cotton Swabs, Big Revolution](#Introduction: Small Cotton Swabs, Big Revolution)

2. [Hygienic Advantages of Individually Packaged Cotton Swabs](#Hygienic Advantages of Individually Packaged Cotton Swabs)

3. [Innovative Breakthroughs in Cotton Swab Production Technology](#Innovative Breakthroughs in Cotton Swab Production Technology)

4. [Quality Control Standards of Professional Cotton Swab Factories](#Quality Control Standards of Professional Cotton Swab Factories)

5. [The Importance of OEM Customization of Medical Cotton Swabs](#The Importance of OEM Customization of Medical Cotton Swabs)

6. [How to Choose a Reliable Cotton Swab Supplier](#How to Choose a Reliable Cotton Swab Supplier)

7. [Conclusion: Future Development Directions of the Cotton Swab Industry](#Conclusion: Future Development Directions of the Cotton Swab Industry)

---

## Introduction: Small Cotton Swabs, Big Revolution

In the field of medical care, every detail matters to patient health and safety. As a fundamental medical consumable, cotton swabs have undergone a significant evolution from simple functionality to safety and security. **Individually packaged cotton swabs** are a key achievement of this evolution, representing the highest standards of safety and security in modern medicine. As the global medical cotton swab market continues to grow, this packaging format is increasingly becoming the preferred choice for both medical institutions and home care.

## Hygienic Advantages of Individually Packaged Cotton Swabs

### Minimizing Contamination Risk

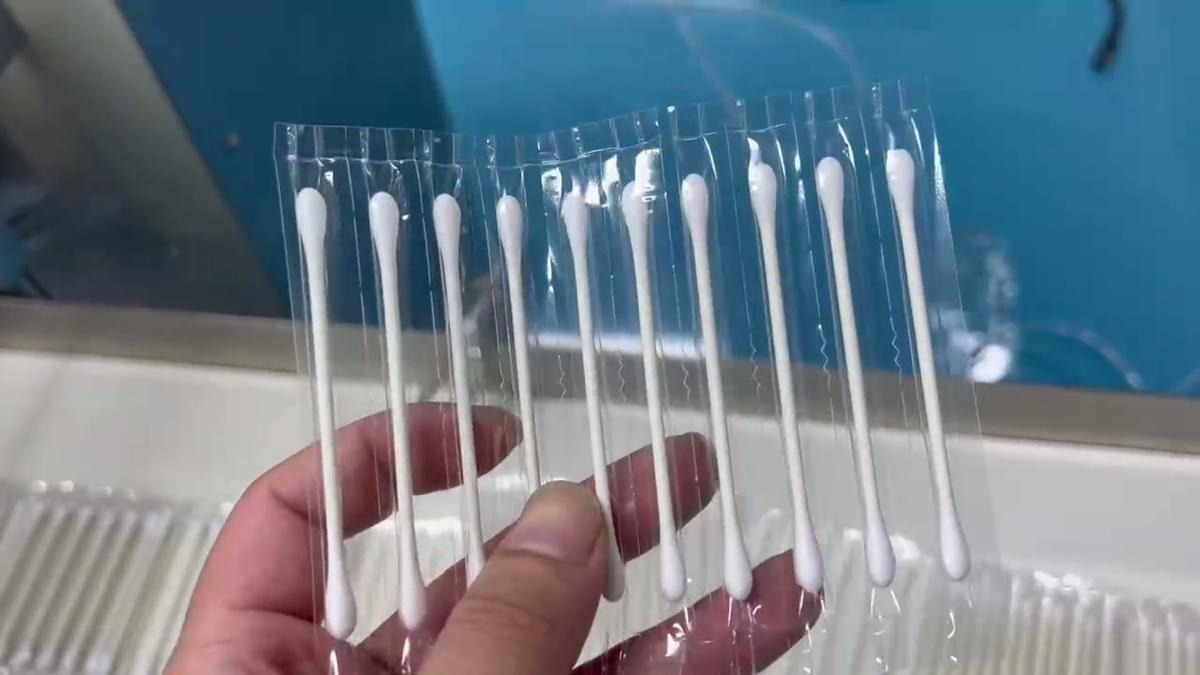

Traditional bulk cotton swabs pose a serious risk of cross-contamination during use. Repeated opening of the packaging exposes the swabs to air, increasing the potential for bacterial and viral contamination. **Individually packaged cotton swabs** perfectly address this issue. Each swab is sealed in its own individual pouch and opened only immediately before use, ensuring sterility until the moment of use.

High-quality **Individually packaged cotton swabs** typically come in a fully sealed, laminated paper or aluminum foil bag with a tear-off hole in the center for quick opening. This packaging design not only effectively blocks external contaminants but also prevents liquid leakage, preserving the cleanliness and functionality of the swab.

### Portability and Convenience

Individually packaged cotton swabs are compact, lightweight, and easy to carry. Whether for outdoor first aid, home care, or clinical visits, you can keep a few on hand for emergencies. Particularly noteworthy are innovative designs, such as shortening the cotton swab stick to 3-4 cm, which effectively prevents puncture injuries caused by struggling infants and young children during use.

### Precise Dosage Control

**Individually packaged cotton swabs** enable precise dosage control, with each package containing only one swab, eliminating waste caused by overuse. For disinfectant swabs that require precise metering (such as iodine swabs), this packaging format ensures accurate and consistent disinfectant content.

### Breakthroughs in Cotton Swab Production Technology

### Advances in Materials Science

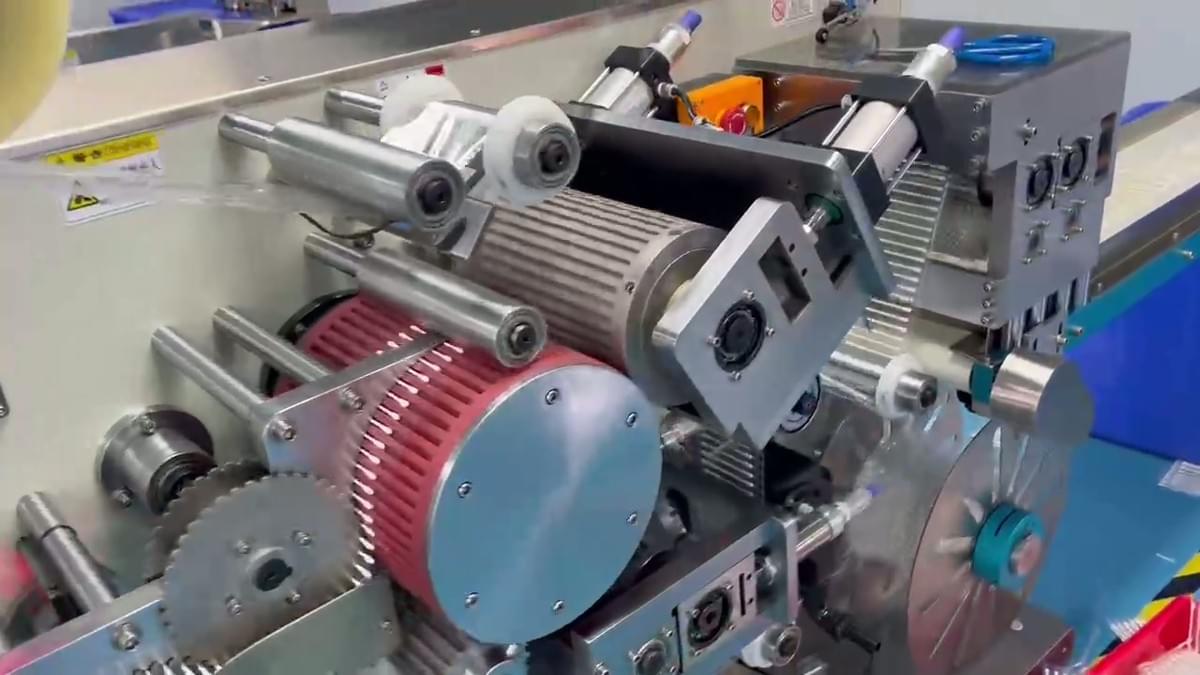

Modern **cotton swab production** has incorporated numerous technological innovations. In addition to traditional wood and plastic, more environmentally friendly options have emerged for cotton swab stick materials. For example, some manufacturers are launching eco-friendly cotton swabs made from biodegradable materials such as polylactic acid powder, straw powder, and bamboo powder. These materials are heated and stirred through a special process, then injection molded. This cotton swab production method not only reduces environmental pollution but also effectively utilizes waste resources.

In cotton material processing, further optimizations have been made to absorbent cotton technology, ensuring that the strength and fineness of cotton fibers remain essentially unchanged before and after degreasing, while also improving water absorption and retention. This is particularly important for medical applications that require the absorption of liquids.

### Innovations in Gluing Technology

Securing the secure bond between the cotton and the cotton swab is a critical step in the cotton swab production process. Professional cotton swab factories utilize a unique process for producing purified cotton swab glue. This process involves heating water to 90°C, then sequentially adding raw materials such as polyvinyl alcohol, sodium hydroxide, and hydrochloric acid. The mixture is then stirred at a constant temperature for a long period of time to form an adhesive that firmly adheres the cotton to the cotton swab. This independently developed glue can replace expensive imported adhesives, reducing the manufacturing cost of purified cotton swabs while ensuring product quality.

### Innovation in Packaging Technology

Modern cotton swab factories have also made significant innovations in packaging. Individually laminated paper bags not only provide a strong seal but are also more environmentally friendly than plastic. The easy-tear design on the bags accommodates the needs of various users (including those with limited mobility), making the bag opening process easier and faster.

## Quality Control Standards of Professional Cotton Swab Factories

### Strict Production Environment Control

Professional cotton swab factories typically have Class 100 sterile/dust-free workshops and high-precision production and inspection equipment to ensure that the cotton swab production environment meets medical-grade standards. Shenzhen Zhongyi Medical New Materials Co., Ltd., for example, specializes in industrial cleanroom cotton swabs and holds multiple national patents. Its products are of the same quality as the world's most advanced.

### Comprehensive Quality Certification System

Reliable cotton swab factories hold a series of international and domestic quality certifications, such as the US FDA, EU CE, and national quality system certifications. These certifications ensure that the entire cotton swab production process meets the high standards required for medical supplies. For example, Zhejiang Hongyu Medical Supplies Co., Ltd.'s products have passed multiple of the aforementioned certifications and have been recognized by renowned brands and retailers such as Disney and Carrefour.

### Continuous R&D Investment

Faced with fierce market competition, leading cotton swab manufacturers are continuously increasing their R&D investment. For example, Zhongyi Medical Health spent five years independently developing paper-rolled purification cotton swabs, successfully developing a purification product that can replace Japanese cotton swabs. This continuous investment in product innovation is key to maintaining market competitiveness.

## The Importance of OEM Customization of Medical Cotton Swabs

### Meeting Differentiated Needs

Medical cotton swab OEM services allow medical institutions and brands to customize products based on their specific needs. This customization can include aspects such as swab length, material, absorbency, and even packaging color. For example, some cotton swab manufacturers offer packaging designs with different colors at each end, separated by a tear-off hole, making it easy for users to quickly distinguish between the two ends of the swab.

Professional medical cotton swab OEM services enable customers to tailor the most suitable product for specific application scenarios, such as hospitals, clinics, and home use. This targeted customization not only improves product usability but also enhances the user experience.

### Brand Enhancement

Through the **Medical Cotton Swab OEM** service, companies can create their own branded medical products, enhancing their brand image and market recognition. Many domestic and international supermarket chains and medical institutions have established long-term retail private-label partnerships with professional **Cotton Swab Factories**. This partnership model ensures product quality while also achieving brand differentiation.

### Cost-Effectiveness

**Medical Cotton Swab OEM services offer customers a more cost-effective solution through large-scale production and technology sharing. Large **Cotton Swab Factories** have mature production lines and supply chain systems, enabling them to effectively control production costs without sacrificing quality. This is crucial for medical institutions and distributors purchasing in large quantities.

### How to Choose a Reliable Cotton Swab Supplier

### Evaluating Production Qualifications and Certifications

When selecting a **Cotton Swab Factory**, first examine its production qualifications and quality certifications. Reputable suppliers often publicly disclose their certifications, such as GMP and ISO13485 Medical Device Quality Management System Certification. These qualifications are fundamental to ensuring product quality.

### Examining R&D and Production Capabilities

A professional cotton swab factory should possess strong R&D capabilities and advanced production equipment. For example, Zhongyi Medical Health has specialized R&D, technical, and production personnel, enabling them to continuously launch new products based on market demand. Furthermore, whether a factory holds multiple national patents is a key indicator of its technological innovation capabilities.

### Understanding Customized Service Capabilities

For customers with specialized needs, the ability to provide OEM medical cotton swab services is a key factor in selecting a supplier. An excellent cotton swab factory can provide one-stop services, from product design and material selection to customized packaging, to meet individual customer needs.

## Conclusion: Future Development Directions of the Cotton Swab Industry

With increasing awareness of medical safety and technological advancements, individually packaged cotton swabs will become the mainstream choice. In the future, cotton swab production will place greater emphasis on environmental friendliness and functionality, with biodegradable materials and intelligent packaging technologies becoming more widely used. Cotton swab factories will continue to improve product quality through technological innovation, while OEM medical cotton swab services will become more flexible and diversified to meet the personalized needs of different users.

**Individually packaged cotton swabs** not only represent an improvement in medical safety standards but also demonstrate the industry's commitment to user experience and environmental protection. Whether you're a large medical institution or individual user, **individually packaged cotton swabs** should be prioritized when choosing cotton swabs to ensure the highest level of hygiene and safety.

As a consumer, understanding the **cotton swab production** process and the **cotton swab factory**'s quality control standards will help you make a more informed choice. For medical institutions and distributors, establishing long-term partnerships with professional **medical cotton swab OEM** suppliers is key to ensuring product quality and a stable supply.

In the field of medical safety, details determine success or failure. Choosing **individually packaged cotton swabs** means choosing a responsible approach to health. With the application of more innovative technologies, **cotton swab production** will become safer, more environmentally friendly, and more convenient, making greater contributions to global healthcare.